Hydraulic Centrifugal Pumps

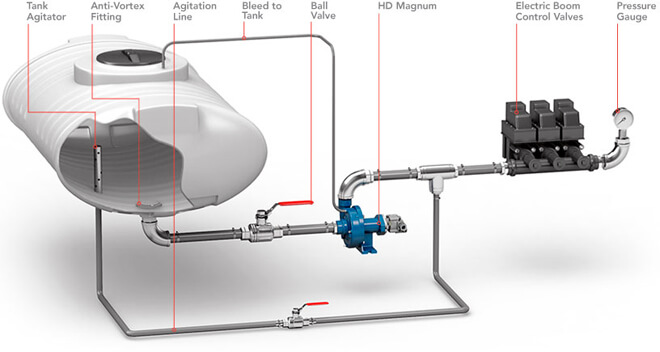

Centrifugal pump design provides good resistance to abrasive solutions and extra flow for agitation. The advantages of the hydraulic pump are mounting versatility, customized performance, and ease of maintenance. They are designed to offer long trouble-free life when matched to a hydraulic power source which will give the correct oil flow and pressure. A wide range of pump outputs can be achieved by simply controlling oil flow and pressure to the hydraulic motor.

We offer a comprehensive range of rugged and dependable products to meet virtually any flow, pressure, material and cost requirement. Tough open and closed center tractor applications challenge any pump’s reliability. Delavan Magnum pumps meet the challenge with superior design, precision engineering and high-quality components.

These hydraulic centrifugal pumps offer a host of features for typical applications such as agriculture spraying equipment and fluid transfer.

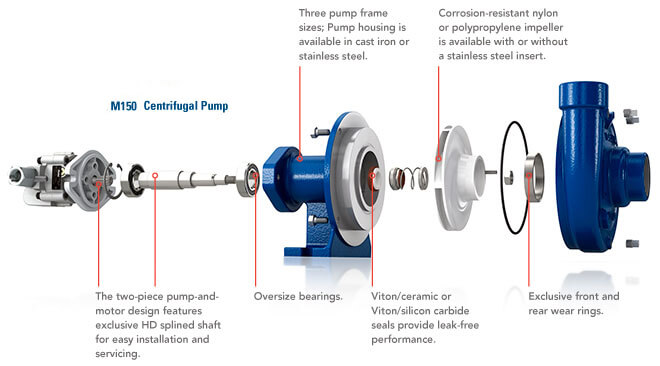

- The matched pump and motor provide optimum hydraulic performance for cooler operation and longer life.

- Exclusive front and rear wear rings balance the impeller and maximize bearing and seal life.

- Corrosion resistant nylon or polypropylene impellers provide extended life.

- Designed and built tough to keep on performing in the most challenging applications for agriculture spray equipment and fluid transfer.

These hydraulically-driven, cast iron and stainless steel pumps provide fluid flow up to 191 GPM and pressure to 140 PSI, at temperatures up to 140°F. They are available in open and closed hydraulic system configurations.

Additional features include a corrosion-resistant nylon impeller and Viton/ceramic seals, as standard. A polypropylene impeller and Viton/silicon carbide seals are available. A standard selection of hydraulic motors offers simple off-the-shelf replacement and covers all applications, and types of tractors. Optimum hydraulic performance is achieved with an optimally matched pump and motor, which provides cooler running temperatures for less heat and longer life.

Additional information on how a centrifugal pump works and how to determine pump capacity.

Downloads: ![]() Installation Manual (494 KB)

Installation Manual (494 KB)![]() HD Magnum Catalog (1.72 MB)

HD Magnum Catalog (1.72 MB)

Hydraulically-Driven Magnum Centrifugal Pumps

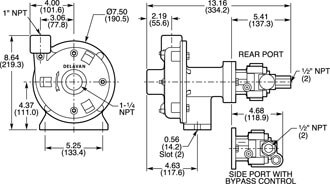

HD Magnum Series M125 HydraCentrifugal Pump

- Max Recommended Temperature: 140°F

- Port Size:

Inlet: 11⁄2 “ FNPT

Outlet: 11⁄4 “ FNPT - Max. Flow: 95 GPM

- Max. Pressure-Shut-off: 130 PSI

- Hydraulic Motor Ports: 1⁄2 SAE x FNPT

- Weight: 29 lbs (13.2 kg)

- Motor Housing: Aluminum

- Pump Housing: Cast iron or stainless steel

- Impeller: Nylon (standard) or polypropylene (optional);

with or without stainless steel inserts - Mechanical Seals:

Cast Iron: Viton/Ceramic Seal (Standard) - Warranty: One Year

| MODEL | DESCRIPTION | MOTOR | PRICE |

| M125C-PM37 | Centrifugal Pump - Cast Iron, Viton/ Ceramic Seal | PM37 | |

| M125C-PM45 | Centrifugal Pump - Cast Iron, Viton/ Ceramic Seal | PM45 | |

| M125S-PM37 | Centrifugal Pump - Stainless Steel, Viton/ Silicone Carbide Seal | PM37 | |

| M125S-PM45 | Centrifugal Pump - Stainless Steel, Viton/ Silicone Carbide Seal | PM45 |

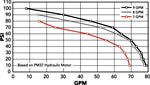

Performance

Pump Flow GPM @ Rated PSI

| Motor Size | Oil Flow (GPM) | 10 | 20 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 | 110 | 120 | 130 |

| PM45* | 11 | 180 | 173 | 165 | 152 | 136 | 123 | 101 | 82 | 61 | 32 | 8 | ||

| 12 | 185 | 177 | 169 | 160 | 151 | 138 | 121 | 103 | 82 | 63 | 45 | 11 | ||

| 13 | 191 | 182 | 174 | 168 | 159 | 145 | 133 | 117 | 101 | 86 | 60 | 36 | ||

| PM37 | 7 | 69 | 68 | 66 | 63 | 55 | 44 | 25 | 16 | |||||

| 8 | 78 | 76 | 75 | 71 | 69 | 61 | 52 | 34 | 15 | |||||

| 9 | 79 | 77 | 76 | 73 | 70 | 63 | 59 | 46 | 30 | 8 |

NOTE: Smaller displacement motors on larger pumps can cause pressures on hydraulic motor to exceed recommended manufacturer’s specifications. Consult factory for details.

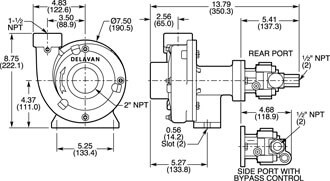

HD Magnum Series M150 HCentrifugal Pump

- Max Recommended Temperature: 140°F

- Port Size:

Inlet: 11⁄2 “ FNPT

Outlet: 11⁄4 “ FNPT - Max. Flow: 191 GPM

- Max. Pressure-Shut-off: 140 PSI

- Hydraulic Motor Ports: 1⁄2 SAE x FNPT

- Motor Housing: Aluminum

- Pump Housing: Cast iron or stainless steel

- Impeller: Nylon (standard) or polypropylene (optional); with or without stainless steel inserts

- Mechanical Seals:

Cast Iron: Viton/Ceramic Seal (Standard)

SS: Viton/Silicon Carbide (Standard) - Weight: 32 lbs (14.5 kg)

- Warranty: One Year

| MODEL | DESCRIPTION | MOTOR | PRICE |

| M150C-PM37 | Centrifugal Pump - Cast Iron, Viton/ Ceramic Seal | PM37 | |

| M150C-PM58B | Centrifugal Pump - Stainless Steel, Viton/ Silicone Carbide Seal | PM58B | |

| M150S-PM58B | Centrifugal Pump - Stainless Steel, Viton/ Silicone Carbide Seal | PM58B |

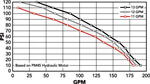

Performance

Pump Flow GPM @ Rated PSI

| Motor Size | Oil Flow (GPM) | 10 | 20 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 | 110 | 120 | 130 |

| PM37* | 7 | 155 | 144 | 127 | 105 | 65 | 21 | |||||||

| 8 | 175 | 170 | 161 | 145 | 126 | 104 | 78 | 43 | ||||||

| 9 | 180 | 172 | 163 | 151 | 138 | 115 | 88 | 64 | 39 | |||||

| PM58 PM58B |

13 | 172 | 165 | 159 | 148 | 136 | 124 | 106 | 86 | 66 | 37 | 12 | ||

| 14 | 180 | 172 | 164 | 156 | 147 | 135 | 120 | 104 | 86 | 69 | 51 | 15 | ||

| 15 | 185 | 174 | 165 | 159 | 150 | 141 | 131 | 118 | 101 | 88 | 63 | 38 |

NOTE: Smaller displacement motors on larger pumps can cause pressures on hydraulic motor to exceed recommended manufacturer’s specifications. Consult factory for details.

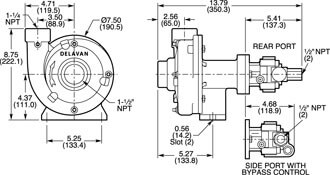

HD Magnum Series M200 Centrifugal Pump

- Max Recommended Temperature: 140°F

- Port Size:

Inlet: 2" FNPT

Outlet: 11⁄2“ FNPT - Max. Flow: 245 GPMs

- Max. Pressure-Shut-off: 145 PSI

- Hydraulic Motor Ports: 1⁄2 SAE x FNPT

- Weight: 33 lbs (15.0 kg)

- Motor Housing: Aluminum

- Pump Housing: Cast iron or stainless steel

- Impeller: Nylon (standard) or polypropylene (optional); with or without stainless steel inserts

- Mechanical Seals:

Cast Iron: Viton/Ceramic Seal (Standard)

SS: Viton/Silicon Carbide (Standard) - Warranty: One Year

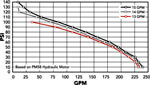

Performance

Pump Flow GPM @ Rated PSI

| Motor Size | Oil Flow (GPM) | 10 | 20 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 | 110 | 120 | 130 |

| PM37* | 7 | 155 | 144 | 127 | 105 | 65 | 21 | |||||||

| 8 | 175 | 170 | 161 | 145 | 126 | 104 | 78 | 43 | ||||||

| 9 | 180 | 172 | 163 | 151 | 138 | 115 | 88 | 64 | 39 | |||||

| PM58 PM58B |

13 | 172 | 165 | 159 | 148 | 136 | 124 | 106 | 86 | 66 | 37 | 12 | ||

| 14 | 180 | 172 | 164 | 156 | 147 | 135 | 120 | 104 | 86 | 69 | 51 | 15 | ||

| 15 | 185 | 174 | 165 | 159 | 150 | 141 | 131 | 118 | 101 | 88 | 63 | 38 |

NOTE: Smaller displacement motors on larger pumps can cause pressures on hydraulic motor to exceed recommended manufacturer’s specifications. Consult factory for details.

Additional Information on Hydraulic Centrifugal Pumps

How Hydraulic Centrifugal Pumps Works

- The pump shaft is driven by a hydraulic motor

- A constant supply of fluid enters the inlet side of the pump (Note: centrifugal pumps cannot be operated dry!)

- As the impeller rotates, centrifugal force pushes the fluid around the pump cavity through the pump housing to the outlet of the pump

- The volume of flow is determined by several factors including: speed, operating pressure, size of the pump

How to Determine Pump Capacity for Your Sprayer

- Pump Capacity (GPM): Boom Requirement (GPM) + Agitation Requirement (GPM)

- Boom Requirement (GPM): Number of nozzles x flow rate per nozzle (GPM at desired PSIG)

- Agitation Requirement (GPM): 5% of total tank volume if using liquids; 10% if using wettable powders

Example:

A boom with extended range 80-04 tips (0.40 GPM at 40 PSIG) and a 200 gallon tank with tank agitation.

Pump Capacity = (17 x 0.40) + (5% of 200)

Pump Capacity = 6.8 + 10.0

Pump Capacity = 16.8 GPM

*See individual hydraulic centrifugal pumps specification pages for complete performance information.