Choosing the Right Nozzle for Your Machine

The orifice size of the nozzle determines the operating pressure of your machine. As a rule of thumb, the smaller the orifice, the greater the restriction of water flowing through the machine. This causes the pressure to increase.

- Choosing a nozzle with too large of an orifice will reduce operating pressure.

- Choosing a nozzle with too small of an orifice will limit water flow and possibly create an excessive load on the machine.

Use the table below to select the properly sized nozzle for your machine. Determine the nozzle size by matching the operating pressure (PSI) of your machine to the gallons per minute (GPM).

| Nozzle Orifice Size | Hole Size | Pounds Per Square Inch = PSI Level of Your Machine | |||||||||||||||||||

500 PSI |

600 PSI |

700 PSI |

800 PSI |

1000 PSI |

1500 PSI |

2000 PSI |

2500 PSI |

3000 PSI |

3500 PSI |

4000 PSI |

4500 PSI |

5000 PSI |

5500 PSI |

6000 PSI |

6500 PSI |

7000 PSI |

7500 PSI |

8000 PSI |

|||

| 2 | .034"/ 0.86mm |

G A L L O N S P E R M I N U T E |

.71 |

.77 |

.84 |

.89 |

1.0 |

1.2 |

1.4 |

1.6 |

1.7 |

1.9 |

2.0 |

2.1 |

2.2 |

2.3 |

2.4 |

2.5 |

2.6 |

2.7 |

2.8 |

| 2.5 | .042"/ 1.07mm |

.9 |

1.0 |

1.0 |

1.1 |

1.3 |

1.6 |

1.8 |

2.0 |

2.2 |

2.3 |

2.5 |

2.7 |

2.8 |

2.9 |

3.1 |

3.2 |

3.3 |

3.4 |

3.5 |

|

| 3.0 | .043"/ 1.09mm |

1.1 |

1.2 |

1.3 |

1.4 |

1.5 |

1.8 |

2.1 |

2.4 |

2.6 |

2.8 |

3.0 |

3.2 |

3.4 |

3.5 |

3.7 |

3.8 |

4.0 |

4.1 |

4.2 |

|

| 3.5 | .048"/ 1.22mm |

1.3 |

1.4 |

1.5 |

1.6 |

1.8 |

2.2 |

2.5 |

2.8 |

3.1 |

3.3 |

3.5 |

3.7 |

3.9 |

4.1 |

4.3 |

4.5 |

4.6 |

4.8 |

4.9 |

|

| 4.0 | .052"/ 1.32mm |

1.4 |

1.6 |

1.7 |

1.8 |

2.0 |

2.5 |

2.8 |

3.2 |

3.5 |

3.7 |

4.0 |

4.2 |

4.5 |

4.7 |

4.9 |

5.1 |

5.3 |

5.5 |

5.7 |

|

| 4.5 | .055"/ 1.40mm |

1.6 |

1.7 |

1.9 |

2.0 |

2.3 |

2.8 |

3.2 |

3.6 |

3.9 |

4.2 |

4.5 |

4.8 |

5.0 |

5.3 |

5.5 |

5.7 |

6.0 |

6.2 |

6.4 |

|

| 5.0 | .057"/ 1.45mm |

1.8 |

1.9 |

2.1 |

2.2 |

2.5 |

3.1 |

3.5 |

4.0 |

4.3 |

4.7 |

5.0 |

5.3 |

5.6 |

5.9 |

6.1 |

6.4 |

6.6 |

6.8 |

7.1 |

|

| 5.5 | .060"/ 1.52mm |

1.9 |

2.1 |

2.3 |

2.5 |

2.8 |

3.4 |

3.9 |

4.3 |

4.8 |

5.1 |

5.5 |

5.8 |

6.2 |

6.4 |

6.7 |

7.0 |

7.3 |

7.5 |

7.8 |

|

| 6.0 | .062"/ 1.57mm |

2.1 |

2.3 |

2.5 |

2.7 |

3.0 |

3.7 |

4.2 |

4.7 |

5.2 |

5.6 |

6.0 |

6.4 |

6.7 |

7.0 |

7.3 |

7.6 |

7.9 |

8.2 |

8.5 |

|

| 6.5 | .064"/ 1.63mm |

2.3 |

2.5 |

2.7 |

2.9 |

3.3 |

4.0 |

4.6 |

5.1 |

5.6 |

6.1 |

6.5 |

6.9 |

7.3 |

7.6 |

8.0 |

8.3 |

8.6 |

8.9 |

9.2 |

|

| 7.0 | .067"/ 1.70mm |

2.5 |

2.7 |

2.9 |

3.1 |

3.5 |

4.3 |

4.9 |

5.5 |

6.1 |

6.5 |

7.0 |

7.4 |

7.8 |

8.2 |

8.6 |

8.9 |

9.3 |

9.6 |

9.9 |

|

| 7.5 | .070"/ 1.78mm |

2.7 |

2.9 |

3.1 |

3.4 |

3.8 |

4.6 |

5.3 |

5.9 |

6.5 |

7.0 |

7.5 |

8.0 |

8.4 |

8.8 |

9.2 |

9.6 |

9.9 |

10.3 |

10.6 |

|

| 8.0 | .072"/ 1.83mm |

2.8 |

3.1 |

3.4 |

3.6 |

4.0 |

4.9 |

5.7 |

6.3 |

6.9 |

7.5 |

8.0 |

8.5 |

8.9 |

9.4 |

9.8 |

10.2 |

10.6 |

11.0 |

11.3 |

|

| 8.5 | .074"/ 1.88mm |

3.01 | - | - | - | 4.25 | 5.21 | 6.01 | 6.72 | 7.36 | 7.95 | 8.50 | 9.02 | 9.50 | - | - | - | - | - | - | |

| 9.0 | .076"/ 1.93mm |

3.2 |

3.5 |

3.8 |

4.0 |

4.5 |

5.5 |

6.4 |

7.1 |

7.8 |

8.4 |

9.0 |

9.6 |

10.1 |

10.6 |

11.0 |

11.5 |

11.9 |

12.3 |

12.7 |

|

| 9.5 | .078"/ 1.98mm |

3.36 | - | - | - | 4.75 | 5.82 | 6.72 | 7.51 | 8.23 | 8.89 | 9.50 | 10.08 | 10.62 | - | - | - | - | - | - | |

| 10 | .080"/ 2.03mm |

3.5 |

3.9 |

4.2 |

4.5 |

5.0 |

6.1 |

7.1 |

7.9 |

8.7 |

9.4 |

10.0 |

10.6 |

11.2 |

11.7 |

12.2 |

12.7 |

13.2 |

13.7 |

14.1 |

|

| 11 | .083"/ 2.11mm |

3.89 | - | - | - | 5.50 | 6.74 | 7.78 | 8.70 | 9.53 | 10.29 | 11.00 | 11.67 | 12.30 | - | - | - | - | - | - | |

| 12 | .087"/ 2.21mm |

4.2 |

4.6 |

5.0 |

5.4 |

6.0 |

7.3 |

8.5 |

9.5 |

10.4 |

11.2 |

12.0 |

12.7 |

13.4 |

14.1 |

14.7 |

15.3 |

15.9 |

16.4 |

17.0 |

|

| 12.5 | .089"/ 2.26mm |

4.42 | - | - | - | 6.25 | 7.65 | 8.84 | 9.88 | 10.83 | 11.69 | 12.50 | 13.26 | 13.98 | - | - | - | - | - | - | |

| 13 | .091"/ 2.31mm |

4.60 | - | - | - | 6.50 | 7.96 | 9.19 | 10.28 | 11.26 | 12.16 | 13.00 | 13.79 | 14.53 | - | - | - | - | - | - | |

| 15 | .096"/ 2.44mm |

5.3 |

5.8 |

6.3 |

6.7 |

7.5 |

9.2 |

10.6 |

11.9 |

13.0 |

14.1 |

15.0 |

15.9 |

16.8 |

17.6 |

18.4 |

19.1 |

19.8 |

20.5 |

21.2 |

|

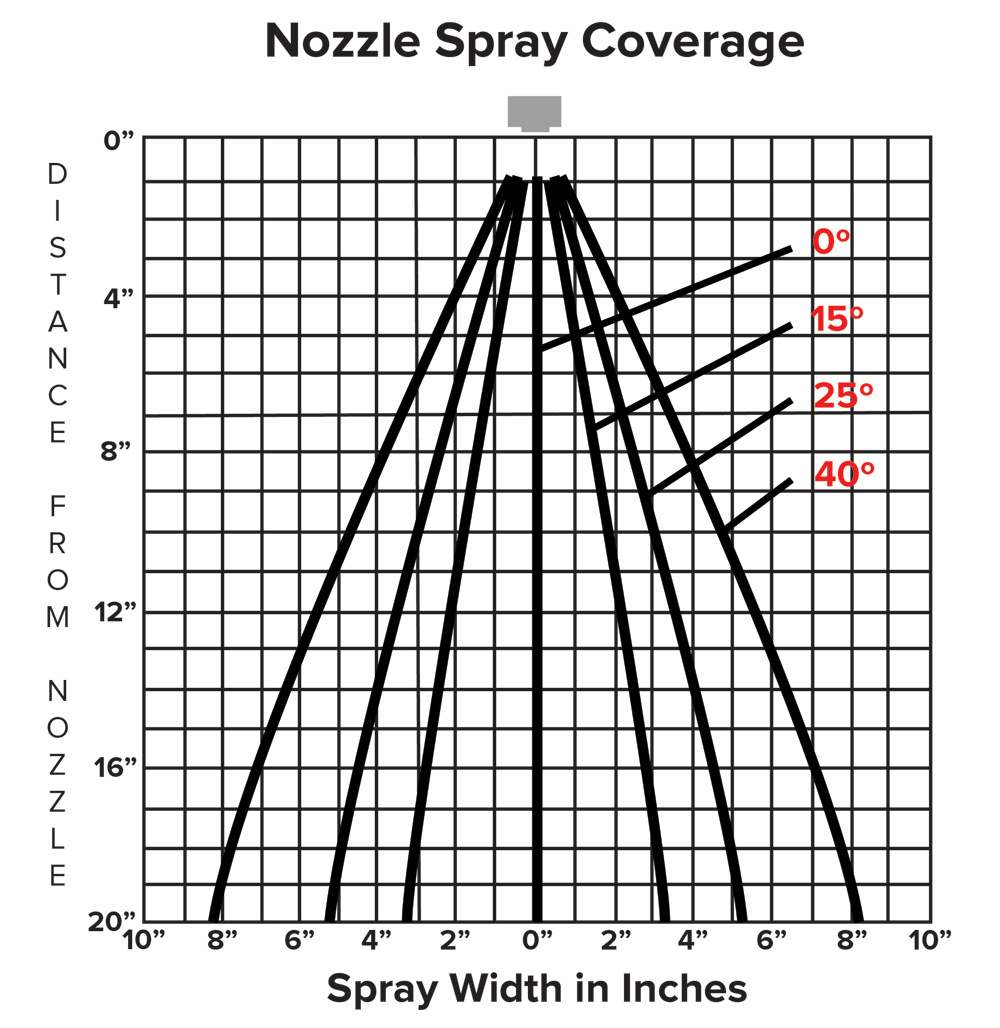

Theoretical Spray Coverage (inches)

| Spray Angle ° |

Distance from the nozzle orifice | Spray Pattern |

Spray Angle |

% Impact/Sq.In. of Theoretical Impact* | ||||||||||

2" |

4" |

6" |

8" |

10" |

12" |

15" |

18" |

24" |

30" |

36" |

FAN |

15 |

30% |

|

15 |

0.5" |

1.1" |

1.6" |

2.1" |

2.6" |

3.2" |

3.9" |

4.7" |

6.3" |

7.9" |

9.5" |

FAN |

25 |

18% |

25 |

0.9" |

1.8" |

2.7" |

3.5" |

4.4" |

5.3" |

6.6" |

8" |

10.6" |

13.3" |

15.9" |

FAN

|

40 |

12% |

40 |

1.5" |

2.9" |

4.4" |

5.8" |

7.3" |

8.7" |

10.9" |

13.1" |

17.5" |

21.8" |

26.2" |

FAN

|

50 |

10% |

50 |

1.9" |

3.7" |

5.6" |

7.5" |

9.3" |

11.2" |

14" |

16.8" |

22.4" |

28" |

33.6" |

FAN

|

65 |

7% |

65 |

2.5" |

5.1" |

7.6" |

10.2" |

12.7" |

15.3" |

19.2" |

22.9" |

30.5" |

38.2" |

45.8" |

|||

Nozzle Recommendation (1 nozzle)

| Size | Flow rate in GPM at: | |||||||||||||

| Orifice | 40 | 100 | 250 | 500 | 600 | 700 | 800 | 1000 | 1200 | 1500 | 2000 | 2500 | 3000 | |

| psi | psi | psi | psi | psi | psi | psi | psi | psi | psi | psi | psi | psi | ||

| 2 | 0.034 | 0.20 | 0.32 | 0.50 | 0.71 | 0.77 | 0.84 | 0.89 | 1.00 | 1.10 | 1.22 | 1.41 | 1.58 | 1.73 |

| 2.5 | 0.039 | 0.25 | 0.40 | 0.63 | 0.88 | 0.97 | 1.05 | 1.12 | 1.25 | 1.37 | 1.53 | 1.77 | 1.98 | 2.17 |

| 3 | 0.043 | 0.30 | 0.47 | 0.75 | 1.06 | 1.16 | 1.25 | 1.34 | 1.50 | 1.64 | 1.84 | 2.12 | 2.37 | 2.60 |

| 3.5 | 0.048 | 0.35 | 0.55 | 0.88 | 1.24 | 1.36 | 1.46 | 1.57 | 1.75 | 1.92 | 2.14 | 2.47 | 2.77 | 3.03 |

| 4 | 0.052 | 0.40 | 0.63 | 1.00 | 1.41 | 1.55 | 1.67 | 1.79 | 2.00 | 2.19 | 2.45 | 2.83 | 3.16 | 3.46 |

| 4.5 | 0.055 | 0.45 | 0.71 | 1.13 | 1.59 | 1.74 | 1.88 | 2.01 | 2.25 | 2.46 | 2.76 | 3.18 | 3.56 | 3.90 |

| 5 | 0.057 | 0.50 | 0.79 | 1.25 | 1.77 | 1.94 | 2.09 | 2.24 | 2.50 | 2.74 | 3.06 | 3.54 | 3.95 | 4.33 |

| 5.5 | 0.060 | 0.55 | 0.87 | 1.38 | 1.94 | 2.13 | 2.30 | 2.46 | 2.75 | 3.01 | 3.37 | 3.89 | 4.35 | 4.76 |

| 6 | 0.062 | 0.60 | 0.95 | 1.50 | 2.12 | 2.32 | 2.51 | 2.68 | 3.00 | 3.29 | 3.67 | 4.24 | 4.74 | 5.20 |

| 6.5 | 0.064 | 0.65 | 1.03 | 1.63 | 2.30 | 2.52 | 2.72 | 2.91 | 3.25 | 3.56 | 3.98 | 4.60 | 5.14 | 5.63 |

| 7 | 0.067 | 0.70 | 1.11 | 1.75 | 2.47 | 2.71 | 2.93 | 3.13 | 3.50 | 3.83 | 4.29 | 4.95 | 5.53 | 6.06 |

| 7.5 | 0.070 | 0.75 | 1.19 | 1.88 | 2.65 | 2.90 | 3.14 | 3.35 | 3.75 | 4.11 | 4.59 | 5.30 | 5.93 | 6.50 |

| 8 | 0.072 | 0.80 | 1.26 | 22.00 | 2.83 | 3.10 | 3.35 | 3.58 | 4.00 | 4.38 | 4.90 | 5.66 | 6.32 | 6.93 |

| 8.5 | 0.074 | 0.85 | 1.34 | 2.13 | 3.01 | 3.29 | 3.56 | 3.80 | 4.25 | 4.66 | 5.21 | 6.01 | 6.72 | 7.36 |

| 9 | 0.076 | 0.90 | 1.42 | 2.25 | 3.18 | 3.49 | 3.76 | 4.02 | 4.50 | 4.93 | 5.51 | 6.36 | 7.12 | 7.79 |

| 9.5 | 0.078 | 0.95 | 1.50 | 2.38 | 3.36 | 3.68 | 3.97 | 4.25 | 4.75 | 5.20 | 5.82 | 6.72 | 7.51 | 8.23 |

| 10 | 0.080 | 1.00 | 1.58 | 2.50 | 3.54 | 3.87 | 4.18 | 4.47 | 5.00 | 5.48 | 6.12 | 7.07 | 7.91 | 8.66 |

| 11 | 0.083 | 1.10 | 17.74 | 2.75 | 3.89 | 4.26 | 4.60 | 4.92 | 5.50 | 6.02 | 6.74 | 7.78 | 8.70 | 9.53 |

| 12 | 0.087 | 1.20 | 1.90 | 3.00 | 4.24 | 4.65 | 5.02 | 5.37 | 6.00 | 6.57 | 7.35 | 8.49 | 9.49 | 10.39 |

| 12.5 | 0.089 | 1.25 | 1.98 | 3.13 | 4.42 | 4.84 | 5.23 | 5.59 | 6.25 | 6.85 | 7.65 | 8.84 | 9.88 | 10.83 |

| 13 | 0.091 | 1.30 | 1.06 | 3.25 | 4.60 | 5.03 | 5.41 | 5.81 | 6.50 | 7.12 | 7.96 | 9.19 | 10.28 | 11.26 |

| 14 | 0.093 | 1.40 | 2.21 | 3.50 | 4.95 | 5.42 | 5.86 | 6.26 | 7.00 | 7.67 | 8.57 | 9.90 | 11.07 | 12.12 |

| 15 | 0.096 | 1.50 | 2.37 | 3.75 | 5.30 | 5.81 | 6.27 | 6.71 | 7.50 | 8.22 | 9.19 | 10.61 | 11.86 | 12.99 |

| 20 | 0.109 | 2.00 | 3.16 | 5.00 | 7.07 | 7.75 | 8.37 | 8.94 | 10.00 | 10.95 | 12.25 | 14.14 | 15.81 | 17.32 |

Surface Cleaner Nozzle Recommendation (2 to 5 nozzles)

| Pump Capacity |

Quantity of Nozzles / Pressure in psi: | ||||

| Size | 2 | 3 | 4 | 5 | |

| Nozzles | Nozzles | Nozzles | Nozzles | ||

| 4 GPM | 2 | 4000 | 1800 | 1000 | 700 |

| 2.5 | 2200 | 1000 | 600 | - | |

| 3 | 1900 | 750 | - | - | |

| 4 | 1000 | - | - | - | |

| 5 GPM | 2 | - | 2800 | 1600 | 1000 |

| 2.5 | 4000 | 1600 | 900 | 600 | |

| 3 | 2700 | 1300 | 600 | - | |

| 4 | 1500 | 650 | - | - | |

| 5 | 1000 | - | - | - | |

| 6 GPM | 2 | - | 4400 | 2250 | 1600 |

| 2.5 | - | 2200 | 1300 | 900 | |

| 3 | 4000 | 1900 | 1000 | 650 | |

| 4 | 2400 | 1000 | 550 | - | |

| 5 | 1400 | 650 | - | - | |

| 6 | 1000 | 450 | - | - | |

| 8 GPM | 2 | - | - | 4000 | 2500 |

| 2.5 | - | - | 2200 | 1500 | |

| 3 | - | 3200 | 1900 | 1100 | |

| 4 | 4000 | 1800 | 1000 | 600 | |

| 5 | 2500 | 1100 | 650 | - | |

| 6 | 1800 | 800 | - | - | |

| 7 | 1300 | - | - | - | |

| 10 GPM | 2 | - | - | - | 4000 |

| 2.5 | - | - | 4000 | 2200 | |

| 3 | - | - | 2750 | 1800 | |

| 4 | - | 2800 | 1500 | 1000 | |

| 5 | 4000 | 1700 | 1000 | 650 | |

| 6 | 2700 | 1300 | 700 | - | |

| 7 | 2000 | 900 | 500 | - | |

| 8 | 1500 | 650 | - | - | |

| 9 | 1200 | - | - | - | |

| 15 GPM | 3 | - | - | - | 4000 |

| 4 | - | - | 3750 | 2200 | |

| 5 | - | 4000 | 2200 | 1400 | |

| 6 | - | 2750 | 1500 | 1000 | |

| 7 | - | 2000 | 1150 | 750 | |

| 8 | 3500 | 1500 | 850 | 550 | |

| 9 | 2800 | 1200 | 700 | - | |

| 10 | 2250 | 1000 | 550 | - | |

| 20 GPM | 4 | - | - | - | 4000 |

| 5 | - | - | 4000 | 2500 | |

| 6 | - | - | 2750 | 1700 | |

| 7 | - | 3600 | 2000 | 1300 | |

| 8 | - | 2800 | 1500 | 1000 | |

| 9 | - | 2200 | 1200 | 800 | |

| 10 | 4000 | 1850 | 1000 | 640 | |

L/MIN - Holes

Holes Diameter Calculation:

PRESSURE > L/MIN > HOLES ∅

Calculation example: having a pump of 200 l/min at 1540 bar, a 6 rear jets nozzle and a 10% pressure loss, it is possible to calculate holes diameter as follows:

P = 150 bar - 10% (pressure loss) = 135 bar

200 l/min ÷ 6 holes = 33,3 l/min for each hole

See below schedule: 135 bar column corresponds to a value of 34,2 l/min (the nearest to 33,3 l/min), value refers to hole diameter, in this case the diameter of each hole is 2,20mm.

| ⇨ | 0,50 | 0,60 | 0,70 | 0,80 | 1,00 | 1,20 | 1,40 | 1,60 | 1,80 | 2,00 | 2,20 | 2,40 | 2,60 | 2,80 | 3,00 | 3,20 |

| PRESSURE BAR |

PUMP FLOW SYSTEM l/min | |||||||||||||||

| 50 | 1,08 | 1,55 | 2,11 | 2,75 | 4,30 | 6,20 | 8,44 | 11,0 | 13,9 | 17,2 | 20,8 | 24,8 | 29,1 | 33,7 | 38,7 | 44,1 |

| 55 | 1,13 | 1,62 | 2,21 | 2,89 | 4,51 | 6,50 | 8,85 | 11,6 | 14,6 | 18,1 | 21,8 | 26,0 | 30,5 | 35,4 | 40,6 | 46,2 |

| 60 | 1,18 | 1,70 | 2,31 | 3,02 | 4,71 | 6,79 | 9,24 | 12,1 | 15,3 | 18,9 | 22,8 | 27,2 | 31,9 | 37,0 | 42,4 | 48,3 |

| 65 | 1,23 | 1,77 | 2,40 | 3,14 | 4,91 | 7,07 | 9,62 | 12,6 | 15,9 | 19,6 | 23,7 | 28,3 | 33,2 | 38,5 | 44,2 | 50,2 |

| 70 | 1,27 | 1,83 | 2,50 | 3,26 | 5,09 | 7,33 | 9,98 | 13,0 | 16,5 | 20,4 | 24,6 | 29,3 | 34,4 | 39,9 | 45,8 | 52,1 |

| 75 | 1,32 | 1,90 | 2,58 | 3,37 | 5,27 | 7,59 | 10,33 | 13,5 | 17,1 | 21,1 | 25,5 | 30,4 | 35,6 | 41,3 | 47,4 | 54,0 |

| 80 | 1,36 | 1,96 | 2,67 | 3,48 | 5,44 | 7,84 | 10,67 | 13,9 | 17,6 | 21,8 | 26,3 | 31,4 | 36,8 | 42,7 | 49,0 | 55,7 |

| 85 | 1,40 | 2,02 | 2,75 | 3,59 | 5,61 | 8,08 | 11,00 | 14,4 | 18,2 | 22,4 | 27,2 | 32,3 | 37,9 | 44,0 | 50,5 | 57,5 |

| 90 | 1,44 | 2,08 | 2,83 | 3,70 | 5,77 | 8,31 | 11,32 | 14,8 | 18,7 | 23,1 | 27,9 | 33,3 | 39,0 | 45,3 | 52,0 | 59,1 |

| 95 | 1,48 | 2,14 | 2,91 | 3,80 | 5,93 | 8,54 | 11,63 | 15,2 | 19,2 | 23,7 | 28,7 | 34,2 | 40,1 | 46,5 | 53,4 | 60,7 |

| 100 | 1,52 | 2,19 | 2,98 | 3,90 | 6,09 | 8,76 | 11,93 | 15,6 | 19,7 | 24,3 | 29,5 | 35,1 | 41,1 | 47,7 | 54,8 | 62,3 |

| 105 | 1,56 | 2,25 | 3,06 | 3,99 | 6,24 | 8,98 | 12,22 | 16,0 | 20,2 | 24,9 | 30,2 | 35,9 | 42,2 | 48,9 | 56,1 | 63,9 |

| 110 | 1,60 | 2,30 | 3,13 | 4,09 | 6,38 | 9,19 | 12,51 | 16,3 | 20,7 | 25,5 | 30,9 | 36,8 | 43,2 | 50,0 | 57,5 | 65,4 |

| 115 | 1,63 | 2,35 | 3,20 | 4,18 | 6,53 | 9,40 | 12,79 | 16,7 | 21,1 | 26,1 | 31,6 | 37,6 | 44,1 | 51,2 | 58,7 | 66,8 |

| 120 | 1,67 | 2,40 | 3,27 | 4,27 | 6,67 | 9,60 | 13,07 | 17,1 | 21,6 | 26,7 | 32,3 | 38,4 | 45,1 | 52,3 | 60,0 | 68,3 |

| 125 | 1,70 | 2,45 | 3,33 | 4,36 | 6,80 | 9,80 | 13,34 | 17,4 | 22,0 | 27,2 | 32,9 | 39,2 | 46,0 | 53,3 | 61,2 | 69,7 |

| 130 | 1,73 | 2,50 | 3,40 | 4,44 | 6,94 | 9,99 | 13,60 | 17,8 | 22,5 | 27,8 | 33,6 | 40,0 | 46,9 | 54,4 | 62,5 | 71,1 |

| 135 | 1,77 | 2,55 | 3,47 | 4,53 | 7,07 | 10,18 | 13,86 | 18,1 | 22,9 | 28,3 | 34,2 | 40,7 | 47,8 | 55,4 | 63,6 | 72,4 |

| 140 | 1,80 | 2,59 | 3,53 | 4,61 | 7,20 | 10,37 | 14,11 | 18,4 | 23,3 | 28,8 | 34,9 | 41,5 | 48,7 | 56,5 | 64,8 | 73,7 |

| 145 | 1,83 | 2,64 | 3,59 | 4,69 | 7,33 | 10,55 | 14,36 | 18,8 | 23,7 | 29,3 | 35,5 | 42,2 | 49,5 | 57,5 | 66,0 | 75,0 |

| 150 | 1,86 | 2,68 | 3,65 | 4,77 | 7,45 | 10,73 | 14,61 | 19,1 | 24,2 | 29,8 | 36,1 | 42,9 | 50,4 | 58,4 | 67,1 | 76,3 |

| 155 | 1,89 | 2,73 | 3,71 | 4,85 | 7,58 | 10,91 | 14,85 | 19,4 | 24,6 | 30,3 | 36,7 | 43,6 | 51,2 | 59,4 | 68,2 | 77,6 |

| 160 | 1,92 | 2,77 | 3,77 | 4,93 | 7,70 | 11,09 | 15,09 | 19,7 | 24,9 | 30,8 | 37,3 | 44,3 | 52,0 | 60,4 | 69,3 | 78,8 |

| 165 | 1,95 | 2,81 | 3,83 | 5,00 | 7,82 | 11,26 | 15,32 | 20,0 | 25,3 | 31,3 | 37,8 | 45,0 | 52,9 | 61,3 | 70,4 | 80,1 |

| 170 | 1,98 | 2,86 | 3,89 | 5,08 | 7,94 | 11,43 | 15,55 | 20,3 | 25,7 | 31,7 | 38,4 | 45,7 | 53,6 | 62,2 | 71,4 | 81,3 |

| 175 | 2,01 | 2,90 | 3,95 | 5,15 | 8,05 | 11,59 | 15,78 | 20,6 | 26,1 | 32,2 | 39,0 | 46,4 | 54,4 | 63,1 | 72,5 | 82,4 |

| 180 | 2,04 | 2,94 | 4,00 | 5,23 | 8,17 | 11,76 | 16,00 | 20,9 | 26,5 | 32,7 | 39,5 | 47,0 | 55,2 | 64,0 | 73,5 | 83,6 |

| 185 | 2,07 | 2,98 | 4,06 | 5,30 | 8,28 | 11,92 | 16,23 | 21,2 | 26,8 | 33,1 | 40,1 | 47,7 | 56,0 | 64,9 | 74,5 | 84,8 |

| 190 | 2,10 | 3,02 | 4,11 | 5,37 | 8,39 | 12,08 | 16,44 | 21,5 | 27,2 | 33,6 | 40,6 | 48,3 | 56,7 | 65,8 | 75,5 | 85,9 |

| 195 | 2,12 | 3,06 | 4,16 | 5,44 | 8,50 | 12,24 | 16,66 | 21,8 | 27,5 | 34,0 | 41,1 | 49,0 | 57,5 | 66,6 | 76,5 | 87,0 |

| 200 | 2,15 | 3,10 | 4,22 | 5,51 | 8,61 | 12,39 | 16,87 | 22,0 | 27,9 | 34,4 | 41,7 | 49,6 | 58,2 | 67,5 | 77,5 | 88,1 |