Commercial Reverse Osmosis Systems

Reverse Osmosis or RO systems are used to provide spot free rinse for car wash. These commercial reverse osmosis systems are designed for high volumes of water daily. Osmosis, by the way, is why drinking salty water (like ocean water) will kill you. When you put salty water in your stomach, osmotic pressure begins drawing water out of your body to try to dilute the salt in your stomach. Eventually, you dehydrate and die. In reverse osmosis, the idea is to use the membrane to act like an extremely fine filter to create drinkable water from salty (or otherwise contaminated) water. The salty water is put on one side of the membrane and pressure is applied to stop, and then reverse, the osmotic process. It generally takes a lot of pressure and is fairly slow.

Reverse osmosis is a filtration process that is often used for water. It works by using pressure to force a solution through a membrane, retaining the solute on one side and allowing the pure solvent to pass to the other side. The membranes used for reverse osmosis have a dense barrier layer in the polymer matrix where most separation occurs. The membranes in these commercial systems are replaceable with a maximum operating temperature of 113 degrees F. Build your system according to how many bays you need to supply and the volume of water expected to be used.

RO Systems

Reverse Osmosis (Spot Free Rinse) Production Systems Only

These are the commercial reverse osmosis systems that produce your spot-free water. Available from 600 to 8700 gallon per day production capacities.

Features:

- Stainless Steel Frame

- Carbon chlorine filter with automatic backwash feature.

- Flow meters for concentrate and permeate levels.

- 10 micron pre-filters.

- Liquid level control for RO water holding tank.

- Stainless Steel stands

- Automatic & manual backwash feature for added membrane life.

- Replaceable Thin-Film Composite membranes.

- Pre-plumbed, pre-wired and tested prior to shipment. Designed to deliver 180 PSI to the membranes.

- 1 Year Warranty

Requires 110V (20 Amp) Service

Does not include storage tank. Suggested size is 225 gallons in vertical style.

Systems up through 800 GPD are 39" H x 15" W x 13" D.

Systems rated from 2200 to 8700 GPD are 54" H x 28" W x 24" D

| MODEL | DESCRIPTION | HP | GALLONS/DAY | PRICE |

| 186DF | Reverse Osmosis Production System | 1/4 | 800 | $5,901.30 |

| 186E0 | Reverse Osmosis Production System | 1 1/2 | 2200 | $6,474.55 |

| 186E1 | Reverse Osmosis Production System | 1 1/2 | 4400 | $9,262.60 |

| 186E2 | Reverse Osmosis Production System | 3 | 6500 | $10,765.10 |

| 186E3 | Reverse Osmosis Production System | 3 | 8700 | $14,115.05 |

![]() Operating Instruction Manual (398,4 KB)

Operating Instruction Manual (398,4 KB)

Reverse Osmosis (Spot Free Rinse) Transfer Systems Only

Self Serve or Combination

These are the commercial reverse osmosis systems that transfer RO Water to the bays. Designed to deliver between 175 and 200 PSI.

Features:

- Stainless steel transfer pumps

- Stainless steel solenoids

- Stainless Steel Frame

- Stainless & plastic connection fittings

- Pre-plumbed, pre-wired and tested prior to shipment

- Bay instruction signs (except on SFS-RA & SFS-TU)

- Run lines and connection fittings

- Power supply "on" light is standard.

- 1 Year Warranty

Specifications: SFS-10, 20, & 30 Systems are 11" W x 18" D x 38" H. All other systems are 11" W x 24" D x 38" H.

| MODEL | DESCRIPTION | HP | VOLTAGE | PRICE |

| 186E9 | 1 Bay Self Serve RO System | 3/4 | 110V | $3,488.50 |

| 186EA | 2 Bay Self Serve RO System | 3/4 | 110V | $3,763.70 |

| 186E4 | 3 Bay Self Serve RO System | 1 | 110 / 230V | $6,111.25 |

| 186E5 | 4 Bay Self Serve RO System | 1 | 110 / 230V | $6,084.35 |

| 186E6 | 1 Self Serve/1 Auto RO System | 2 | 110V | $6,193.15 |

| 186E7 | 2 Self Serve/1 Auto RO System | 2 | 110V | $6,043.40 |

| 186E8 | 3 Self Serve/1 Auto RO System | 3 | 230V | $7,137.80 |

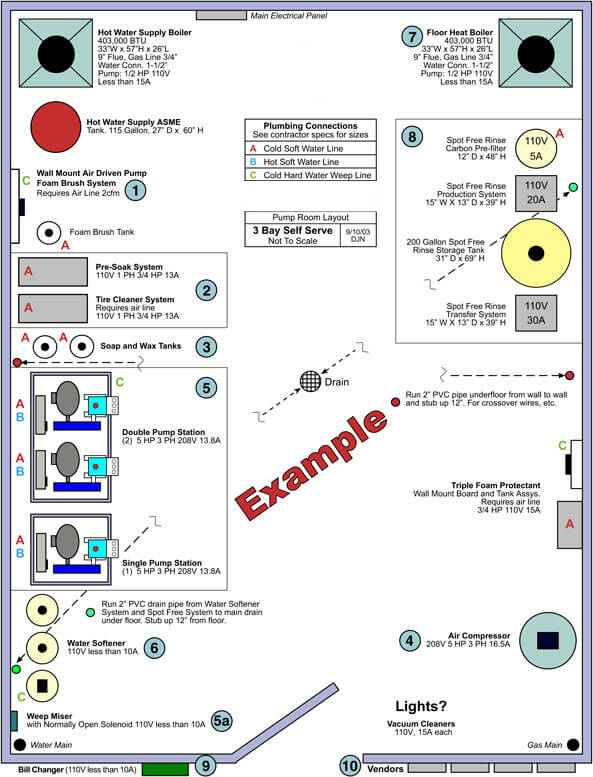

Typical Pump Room Layout

Note: This is a typical 3-Bay pump-room layout which includes the commercial reverse osmosis systems, installations and buildings may vary causing changes to this layout to be necessary!

- Foam Brush (Pump System): Height: 53", Width: 24", Depth: 12". Water inlet is 3/4" FGTH. 110 Volt required. (24 volt hookup from pumping station required).

- Tire Cleaner & Pre-Soak Systems: Height: 53", Width: 12", Depth: 24". Water inlet is 3/4" FGTH. 110 Volt required. (24 volt hookup from pumping station required).

- Soap & Wax Tanks (Automatic-Liquid): 20 Gallon Height: 22-1/8", Diameter is 18". Water inlet is 3/4" GHT. Vinyl run lines can be run from solenoids into top of the tank through the lid.

- Air Compressor: Sized for 1 cfm per bay. 110 volt required. 3/8" connector from compressor to foam brush tire cleaner systems.

- Pump Stations: Height: 62", Depth: 29", Width: 22" on single and 44" on double units. Hot and cold water inlets are 3/4" MGTH. Attach cold water solenoid to main with hoses supplied. Attach hot water solenoid to water heater with hoses supplied. (Note: Heaters are normally mounted above pump stations.) Electrical requirements are as follows: 208 or 230 volt, single or three phase required for each station. Local installation will dictate requirements.

- a Weep System: Includes thermostat and solenoid. Ports are 3/8" FPT. Tap into hard water line, run separate line to solenoid valve. Plumb valve with unions (not included) and run from valve to weep inlet on pump stations, continue run to weep inlet on brush system. Attach thermostat to solenoid. 110 volt required.

- Water Softener: Each softener includes (1) brine tank and (2) mineral tanks. 110 volt required.

- Floor Heat System: Varies with number of bays. See separate floor heat diagram for proper hookup.

- Optional Spot-Free Rinse Systems: Hookup will vary with specific system.

- Bill Changer: Mounts into pump room wall, size will vary with specific model. 110 volt required.

- Vending Machines: Mount to external walls. Height: 42", Width: 12-1/2", Depth: 5-1/2".

Typical Electrical Specifications and Requirements for Commercial Reverse Osmosis Systems

- All necessary components required for electrical hookup of the items shown or quoted on the enclosed sheet at the amp draws shown. This would include supplies and labor.

- Running low-voltage lines from equipment to coin meters; includes pulling of wire and labor. (Run lines are supplied in the wiring package shown on the quote sheet.)

- Mounting and wiring of all vacuums to vac islands, including supplies and labor.

- Run wires from foam brush, tire cleaner systems, etc. to main electrical panels on pumping stations. Includes supplies and labor.

- High voltage wiring from breaker box to all pump panels and from pump panels to pump motors. Includes supplies and labor.

- Electrical hookup of all electrical components on all optional items (foam brush, tire cleaner, soap tanks, water softener, bill changer, spot-free rinse, etc.). Includes supplies and labor.

- Run lines and supplies for all internal bay lights and external lot lighting. (Note: Some fixtures may be supplied in equipment bid.)

- External lot lighting if required by contractor.

- Wiring of thermostats: weep and floor heat. Electrician must be present when thermostats are activated for initial trial run.

- Wiring of motor and pump on floor heat system. Includes supplies and labor.

- If a high pressure automatic is to be installed with the self-serve equipment, separate electrical specifications and requirements are available upon request.

See Also

We offer extensive line of wash water recovery and water filtration. We also provide water containment and water recycle / treatment that can greatly help your business and the environment.

Starting a new business? Check out our car wash equipment. We have vacuums, detailing stations, boom bay packages, car wash drying systems, pump stations and more.

|

Can this page be improved? Is the information complete and easy to understand? We are always looking to improve our website, so please feel free to give us your comments or suggestions. Thanks for helping us serve you better! |